PMC 1.jpg

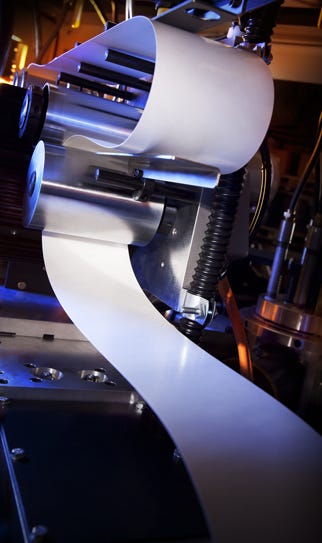

Paper cups are one of the most common containers in our daily lives. However, like many of the seemingly simple packages we use every day, the best forming machines for making paper cups and cardboard cans employ advanced engineering and systems design combined with high-performance components to sustain the production of thousands of containers per hour, 24 A few hours a day.

Paper Machinery Company It is one of the world’s leading suppliers of high-performance paper cups, cardboard cans and customized cardboard packaging forming machines. With more than 1,500 installations in more than 45 countries, PMC has a deep understanding of the changing paper container needs of converters, food service and beverage company suppliers.

PMC recently decided to create a new paper container forming machine designed to provide a more flexible platform that allows for faster and easier tool changes to support a wider range of container sizes and dimensions. This is the PMC 2000S—the industry’s first fully servo-driven molding machine. To control the new PMC 2000S, PMC selected a complete servo drive, motor and motion control platform from the drive and control experts at Bosch Rexroth AG.

Globally, consumer goods suppliers are launching an increasing number of products

PMC 2.jpg

To suit regional, ethnic, lifestyle, age-related and gender-specific tastes. This drives demand for paper machines that can run different containers—sometimes two, three or four different containers—during the week.

PMC is a specialist in leading machinery for the manufacturing industry. Prior to the launch of its latest machines, all of the company’s platforms used mechanical drive shafts and cams to power major machine components. “For a growing customer base, you need to run multiple sets of tools on one machine,” said John Baumgartner, president of PMC. “Our servo-driven machines will serve customers with these types of mold change requirements significantly better.”

“S” stands for servo

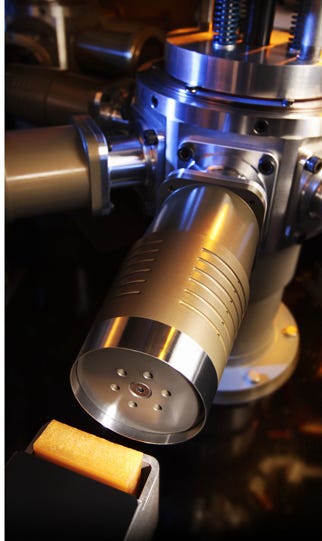

The new PMC 2000S is an 18-axis machine with three main parts: a transfer turret that feeds the container sidewalls into the machine; a transfer turret that processes the sidewalls via multiple wrapping, gluing, seaming and bottom application stations index; and crimping turrets for crimping the top edges of containers.

This configuration (the “top” of the machine) is similar to other PMC machines. What differs from the PMC 2000S is the complete Rexroth IndraMotion MLC (Motion Logic in Controller) motion, logic and drive platform of the control system. Combining the advanced Rexroth IndraDyn T direct drive motor and the compact IndraDrive Cs servo drive, Rexroth has equipped the PMC 2000S with a fully integrated drive and control platform capable of producing up to 200 cups/minute.

Equally important, the Rexroth IndraMotion MLC platform replaces the mechanical cams of 18 machine axes with digital electronic cams. It creates an operational framework that supports faster product transitions. “Imagine changing from one complete tool set to another within a single shift,” Baumgartner said. “In addition, each station on the machine runs its own unique electronic cam profile that is optimized for that station’s motion and integrated and synchronized with the entire machine.”

Rexroth’s IndraMotion MLC is a controller-based integrated motion logic platform that combines innovative software and firmware capabilities with technical capabilities specific to the printing and converting industry. It features an extensive library of motion sequence software, providing machine builders with maximum flexibility to configure the optimal control platform for their application.

IndraMotion MLC also provides a range of sophisticated programming tools to build and fine-tune electronic cams and motion sequencing tools, which gave Rexroth a key advantage when PMC was evaluating which platform to use to control the PMC 2000S.

Liz Lind, PMC controls manager, said PMC has used Rexroth servo technology in the feed subsystem on its machines in the past.For this project, we evaluated multiple servo component suppliers and integrators, including Rexroth and its local automation dealer partners, she said CMA/Flodyne/Hydradyne (CMAFH). “We invited them to participate in a competitive comparison, placing their servo drive platform and direct drive on a test spindle turret so that PMC could evaluate a wide range of performance parameters,” she said.

Each supplier designs and manufactures controls, drives and

PMC 3.jpg

Motor platform and mounted on test spindle turret. PMC then tested each company’s platform, evaluating its ease of use, ability to perform a full range of motion sequences, and system tuning and diagnostic tools.

“We take many different types of readings; whatever the system provides, such as oscilloscope traces,” Lind said. “Rexroth has an excellent oscilloscope tracking system in its IndraMotion platform, which we use constantly to tune the motor and test its position. Based on the performance of the direct drive motor, control system and troubleshooting system, Rexroth is a clear winner: the winner.”

Once the IndraMotion MLC platform has been selected, building and modifying the electronic cam is one of the most critical engineering steps. Rexroth’s CamBuilder program is the perfect solution to this challenge. CamBuilder is a Windows-based software tool designed for rapid, complex design, testing and fine-tuning of electronic cams. Lind says her team has found CamBuilder invaluable. “It’s very easy to use and offers many different configuration types and options for building your cam tables,” she said. “Once the table is built, you can enter motion sequence information numerically and view it as a graphical description. You can also move the graph around and see the values change.”

Lind said CamBuilder also enables PMC to export .csv files that can be imported into an Excel spreadsheet and converted into AutoCAD drawings to visualize the true motion of the axes. Lind said that by using the oscilloscope function in the IndraMotion platform, they can run each machine axis individually or in combination, capture motion data and verify that the actual motion results are the same as the theoretical results.

“In the theoretical world, you might build something, but in the real world, the mechanism might have stiffness or clearance, so you don’t get to the exact place you think you should,” Lind said. “Using the tools provided by the Rexroth platform, we can build the cam table and verify its reliability.”

Another valuable feature offered by the IndraMotion platform is remote diagnostics. PMC can access any PMC 2000S control platform anywhere via the network and solve machine problems down to a single servo drive. This will significantly increase machine uptime and reduce maintenance and support costs.

One of the other engineering challenges posed by the PMC 2000S was selecting and sizing the motors for each axis; specifically the direct drive motors used to turn the spindle turret, transfer turret and clamping turret. Lind says the motors for these turrets are required to move profiles with very high demands. “The contours we moved were very aggressive, very precise, and needed to be done in a precise amount of time,” she said. “The strength and high pole count of the Rexroth direct drive motors driving the spindle turret enable motions that other suppliers’ direct drive motors cannot.”

Rexroth’s IndraDyn T series torque direct drive motors are optimized for high torques of up to 13,800 Nm (Newton meters). They have a high pole count, allowing for exceptional stiffness, stable motion and high stiffness at the end points. This enables PMC to meet another key machine requirement: stopping machine movement within one index when required (for example, if a container fails to eject onto a cup diverter) without damaging the machine’s mechanical system or the drive itself.

PMC is targeting its new machine at the paper cup and container manufacturing market looking for lower cost machines. PMC’s Baumgartner said Rexroth’s servo drive platform is helping to achieve this goal.

Lind added that one of the keys to improving PMC’s ability to develop P

PMC 4.jpg

What makes the MC 2000S faster is the engineering support and insights provided by Rexroth and CMAFH, who not only provide on-site programming and selection assistance, but also provide local component inventory.

“One of the reasons we chose Rexroth and CMAFH was their flexibility and excellent engineering support,” she said. “This is a different control system than what we are used to and they were happy to help us learn it. We worked well together to design this software package.”

Bosch Rexroth AG, 800-739-7684.

www.boschrexroth-us.com

CMA/Flodyne/Hydradyne,

262-781-1815. www.cmafh.com

Paper Machinery Company

414-362-8231. www.papermc.com